Blog

- Minimalist outer box design

- Neatly organized internal layout with a rigid white protective tray

- The inverter itself resembles a small water bottle — perfectly sized to fit into a vehicle’s cup holder.

Key exterior details:

- Soft rubber base with printed specifications

- A twist-to-open top revealing the 220V AC output socket, two USB ports conveniently built into the lid

- Total weight: 612 grams

The design is practical, compact, and car-friendly.

2. 🔌 Functional Testing Before Teardown

Before opening the device, several functional tests were conducted.

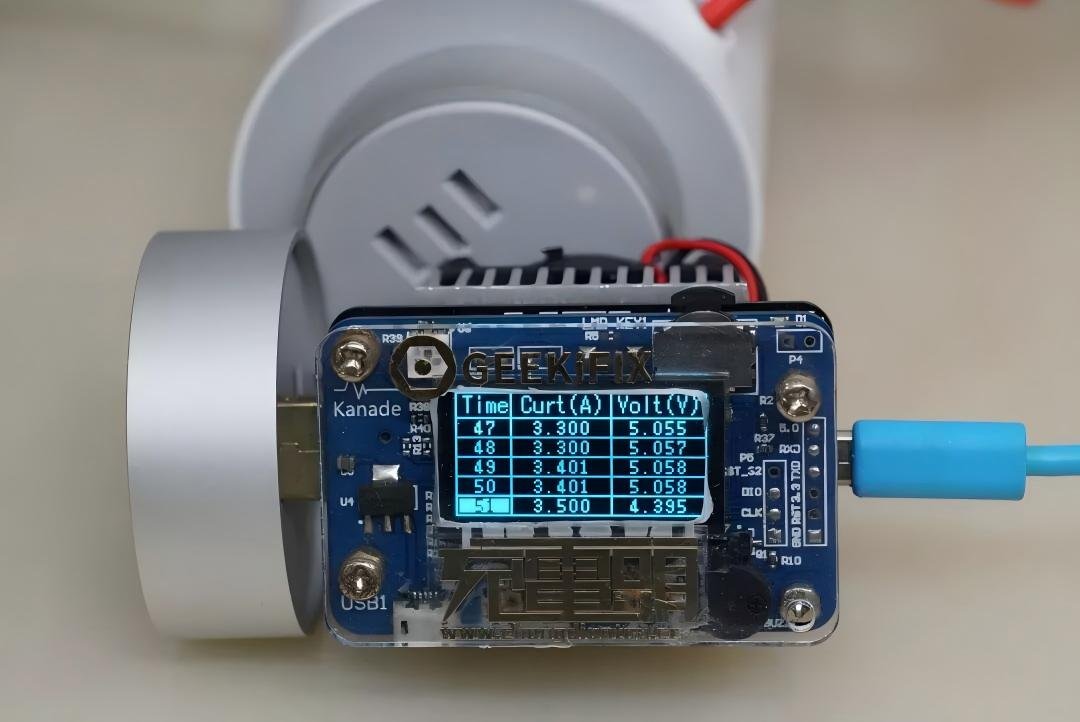

USB Performance

Using the ChargerLab POWER-Z FL001 SUPER analyzer:

- Maximum output: 3.4A

- Supports Apple 2.4A

fast-charging protocol

fast-charging protocol - No support for other fast-charge standards

Charging experiments:

- iPhone 7 Plus charging at 2A

- Simultaneous USB output supported

AC Output Performance

- Output voltage: 228.6V

- Output frequency: 52.7Hz

Everything worked as expected for a modified-sine-wave inverter.

3. 🛠 Full Teardown: Inside the Mijia Car Inverter

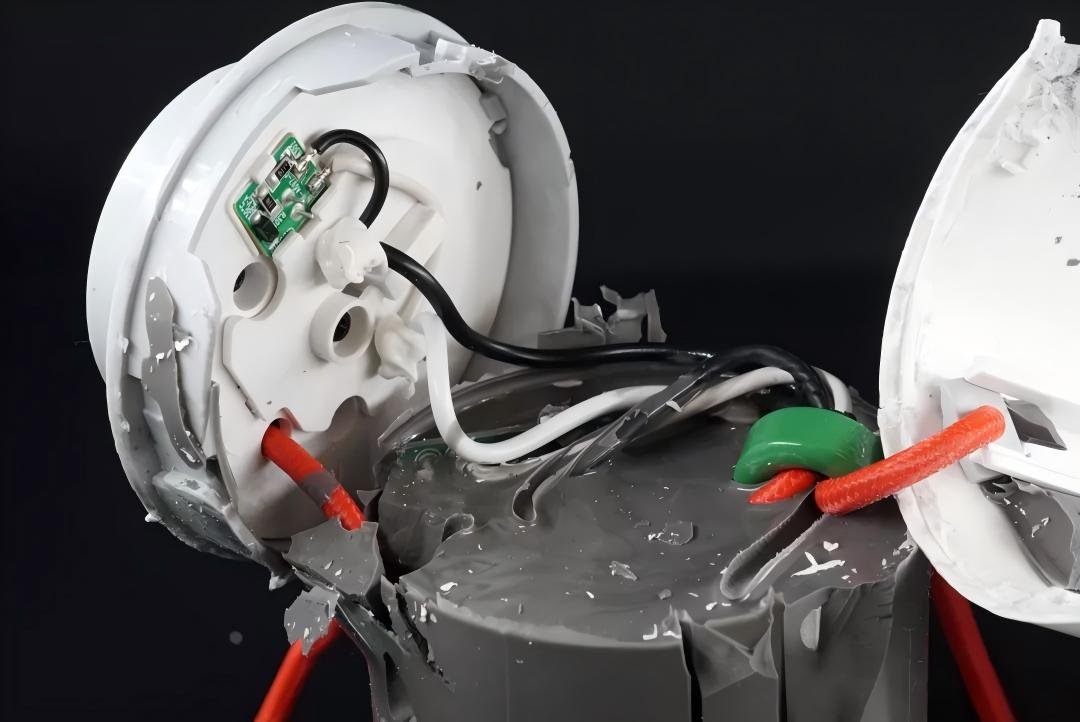

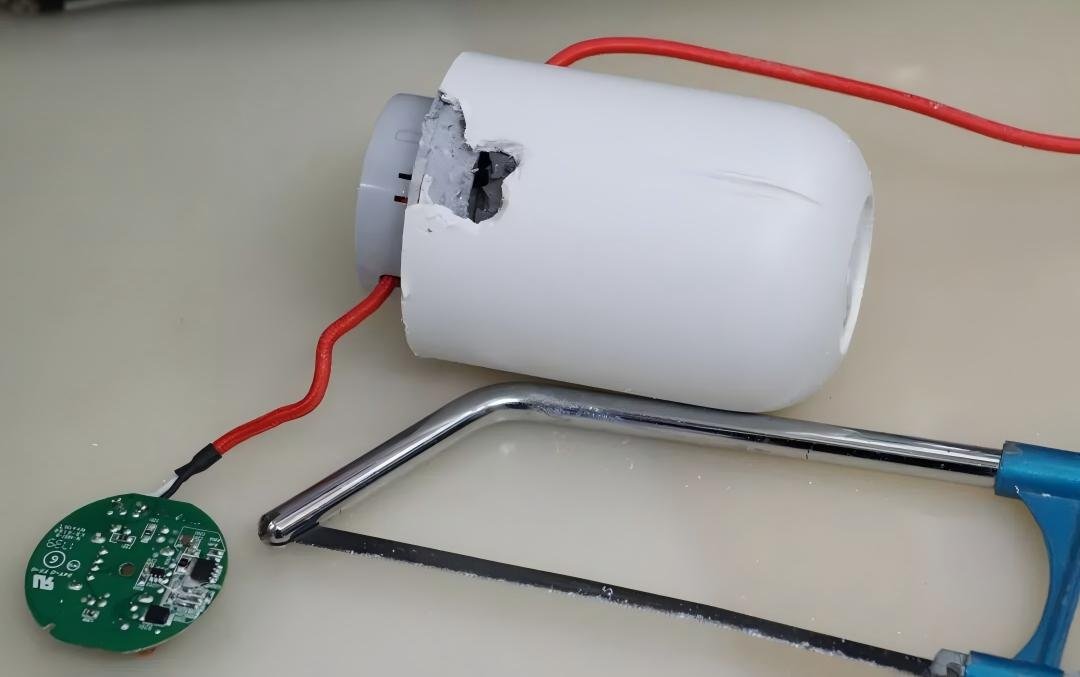

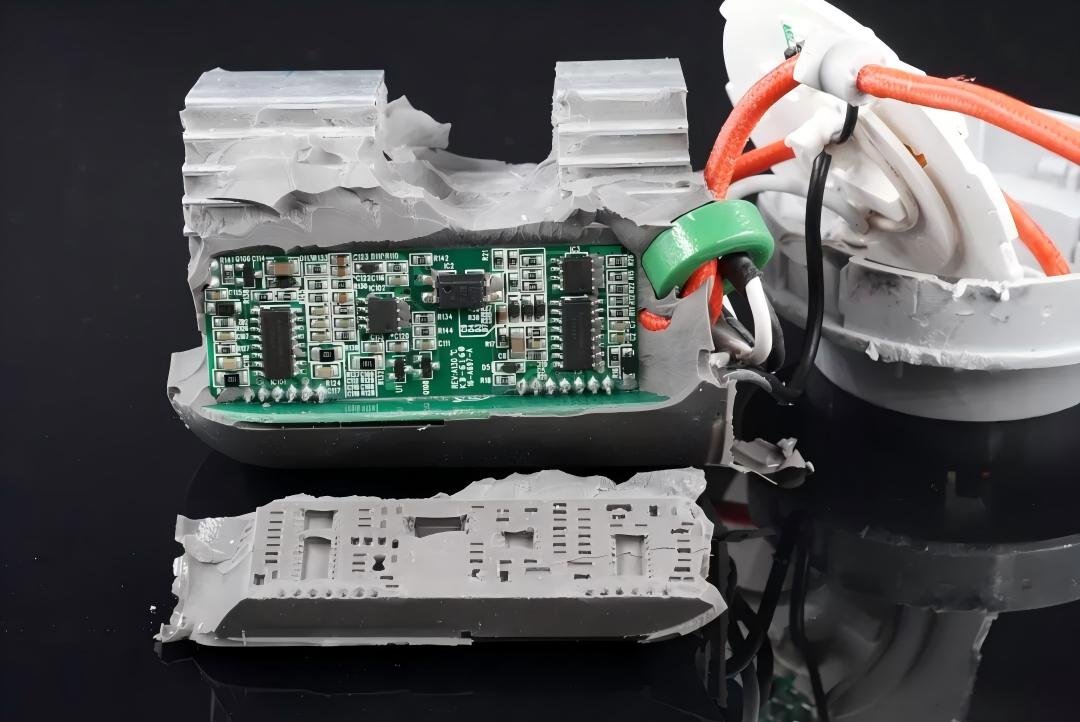

After performance testing, we move to the teardown — and Xiaomi certainly didn’t make it easy.

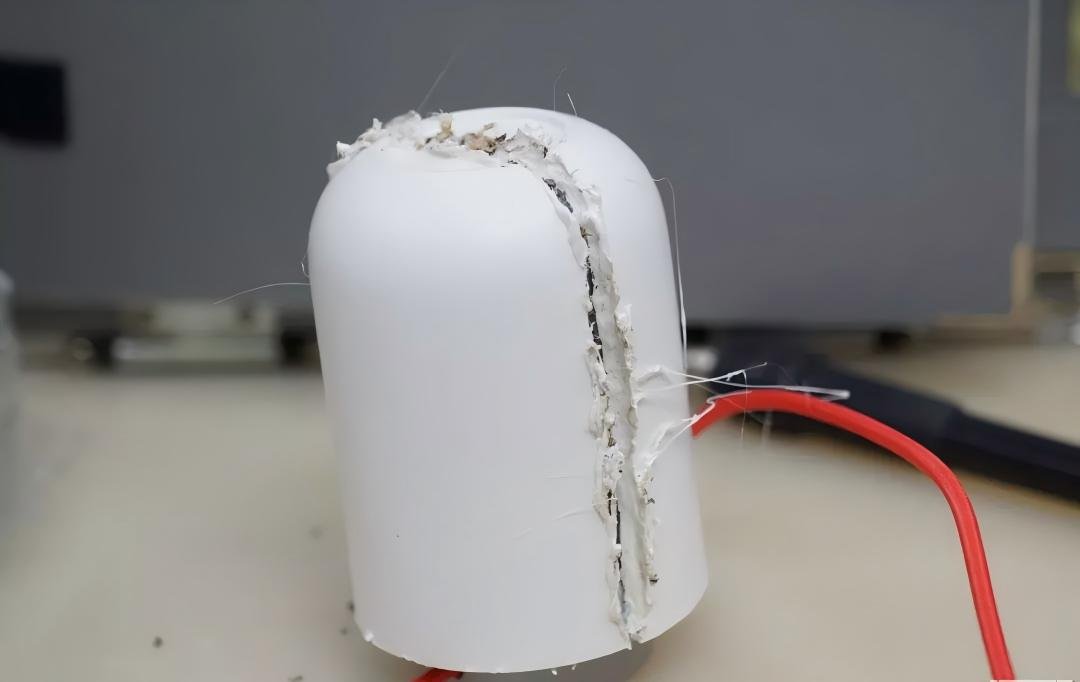

Opening the Shell

Tools needed: a saw + soldering iron to soften the casing.

Inside, the entire inverter is filled with thermal conductive potting compound:

- Enhances heat dissipation

- Improves structural rigidity

- Reduces vibration

- Explains the device’s substantial weight

The potting material required significant effort to remove.

4. 🔍 Internal Architecture Breakdown

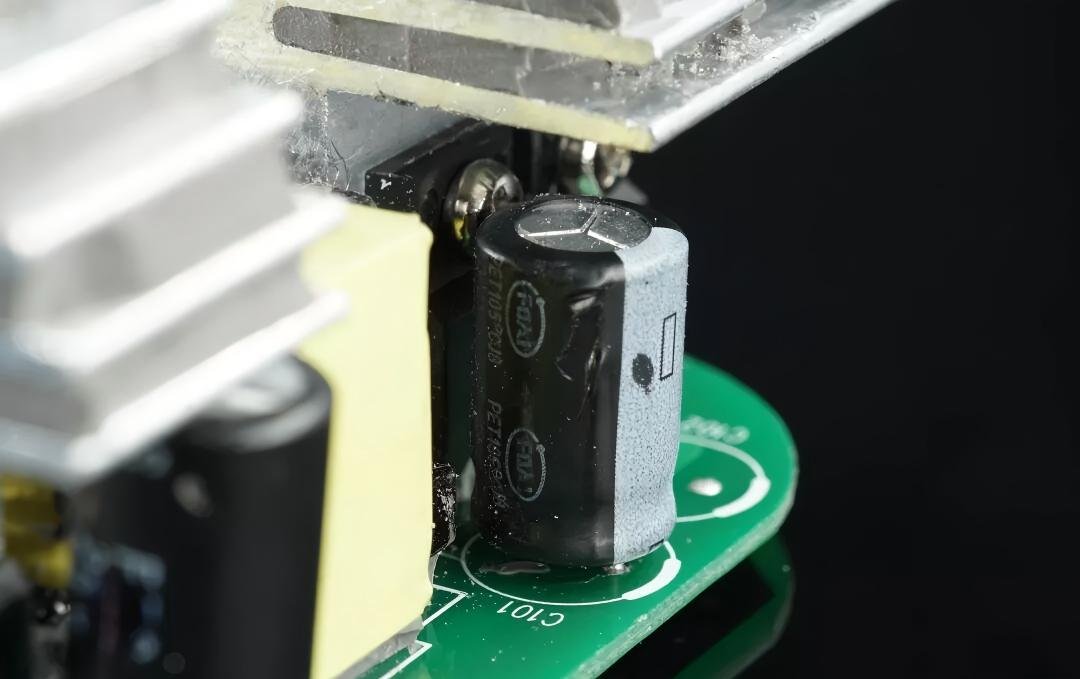

4.1 Input Section

- Thick input wires with a magnetic ring for EMI suppression

- Primary filtering capacitor

- Clean soldering with silicone reinforcement

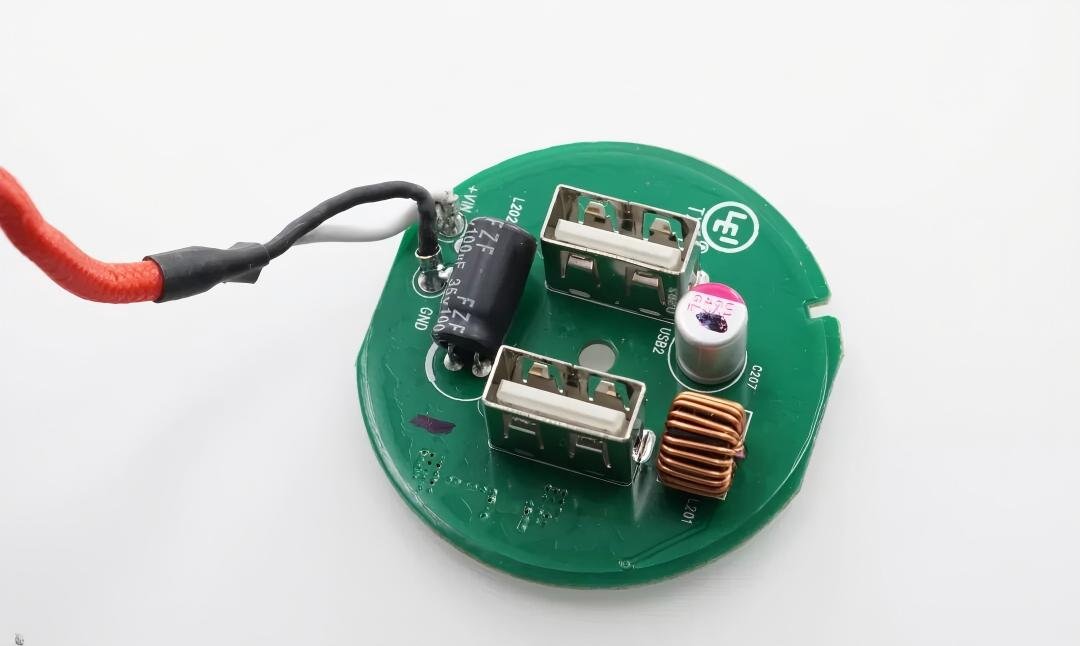

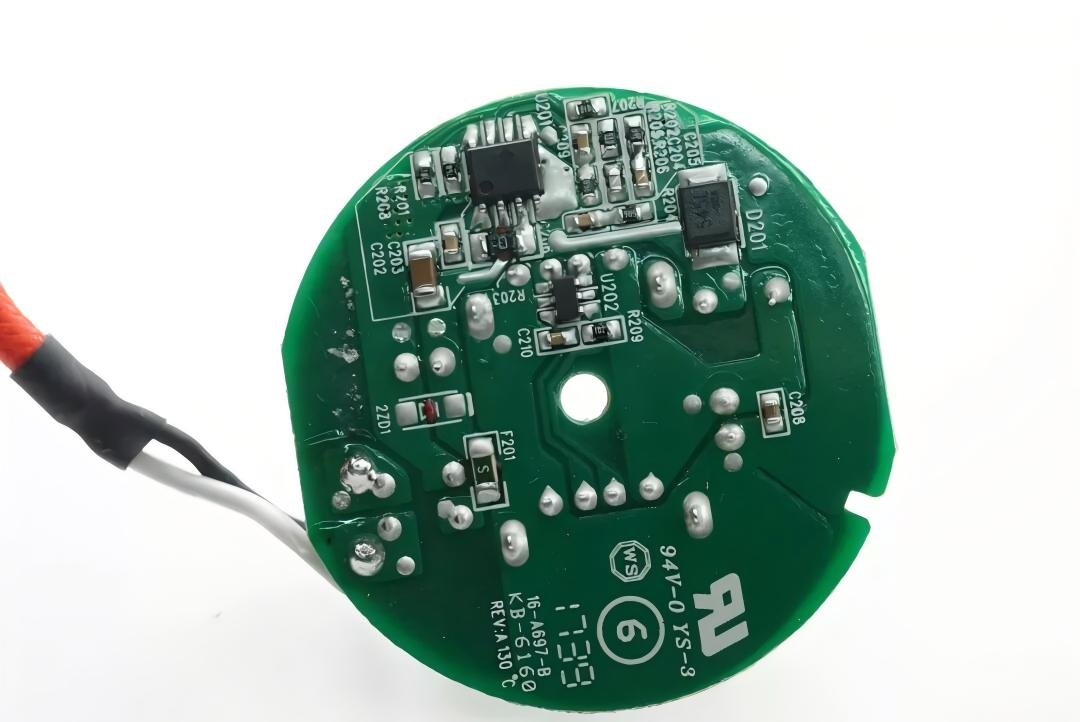

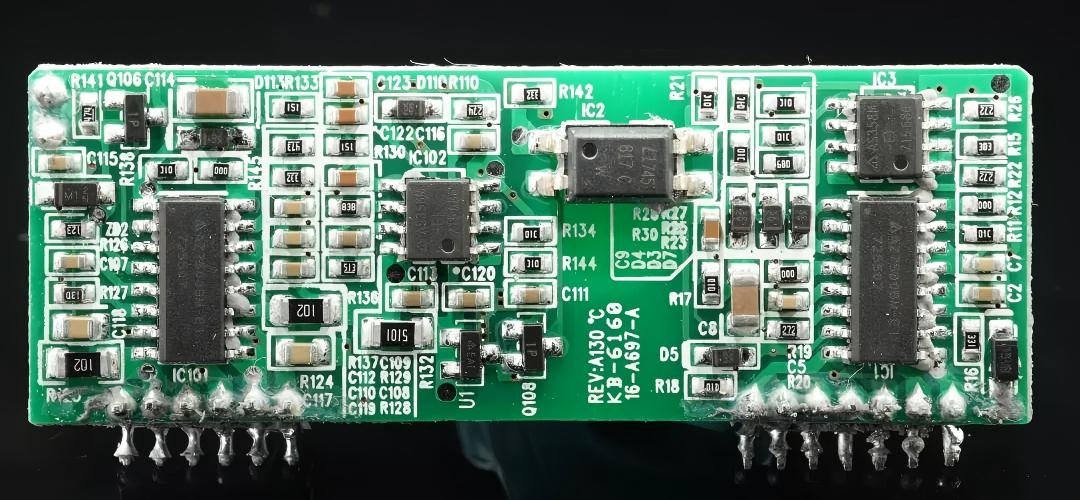

4.2 USB Module (Built into the Lid)

Disassembling the inverter’s cover reveals a working principle similar to that of a car charger.

The lid is made of aluminum alloy, and the inside is plastic.

The USB section resembles a compact car charger:

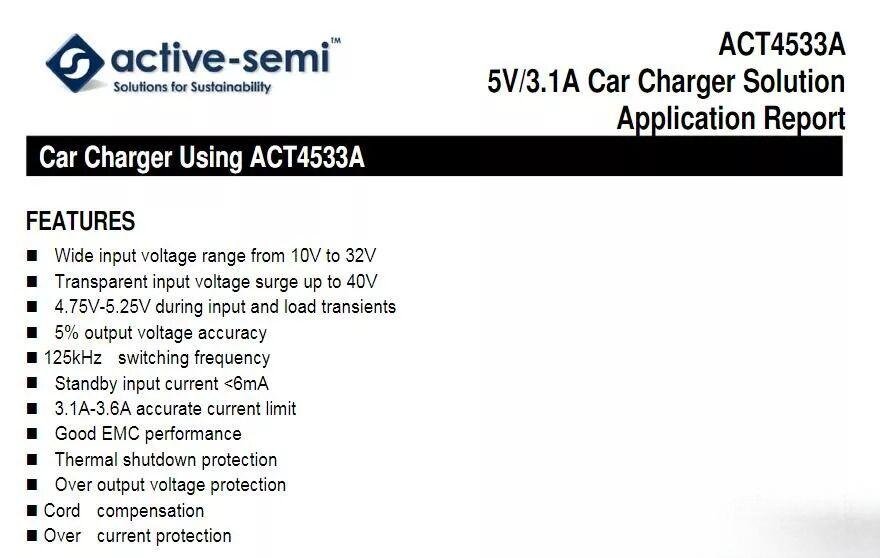

- One electrolytic input capacitor, one solid-state output capacitor

- Uses ACT4533 + dual-protocol recognition IC

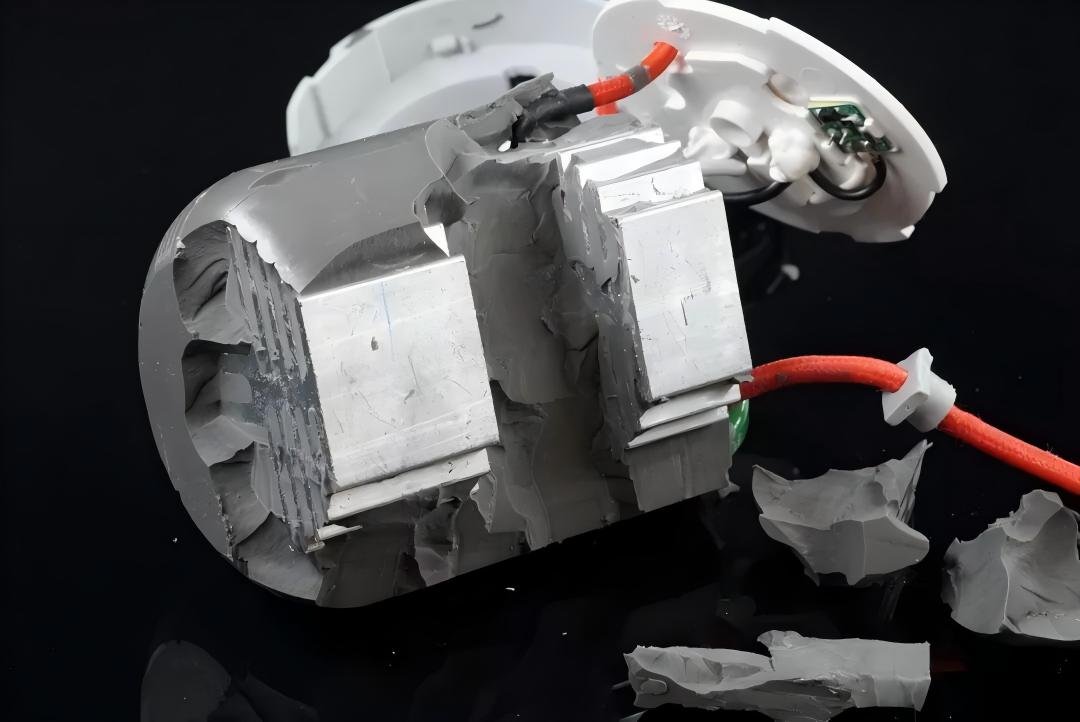

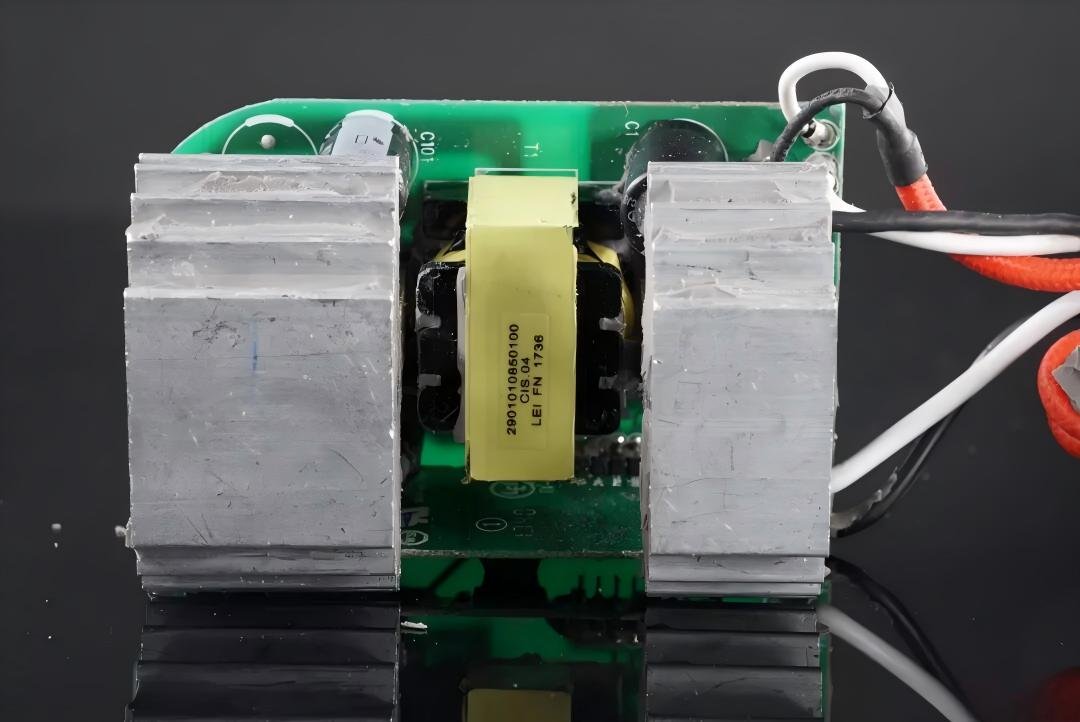

4.3 Power Conversion Stage

After removing the cap, the difficult process of removing the adhesive begins.

Two major aluminum heat sinks sit on each side:

- One for the boost (step-up) stage

- One for the output modulation stage

Between them is the main step-up transformer.

A small driver board on the side manages MOSFET control.

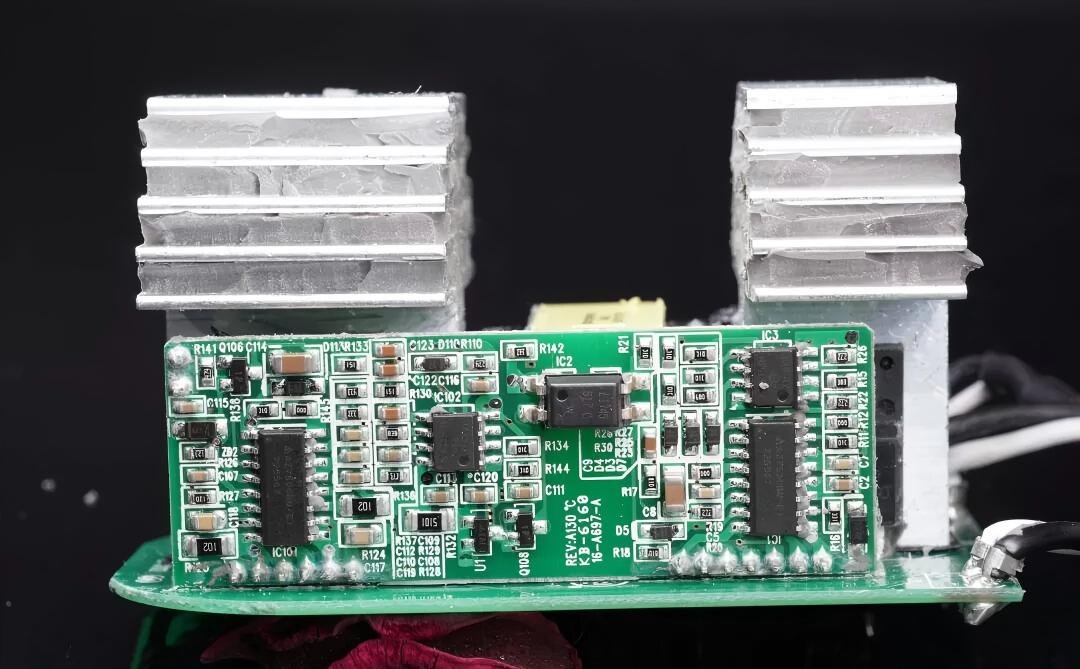

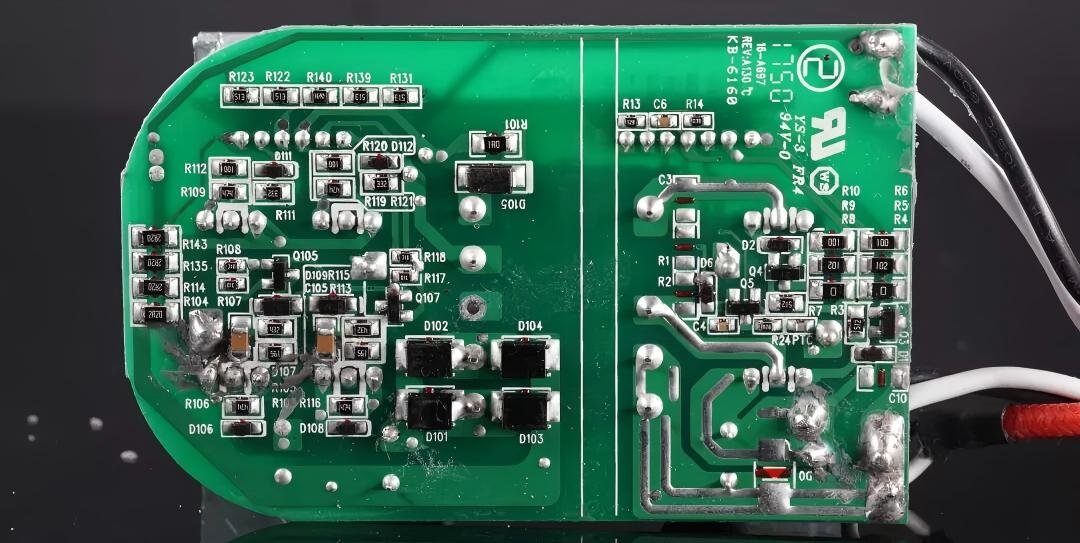

4.4 Control Logic

Both sides of the system use a familiar power control scheme:

- KA7500 PWM controller + LM358 operational amplifier

- Left side KA7500: AC output modulation

- Right side KA7500: driving MOSFETs for DC step-up

This confirms the inverter uses a “modified sine wave” design, widely adopted for mid-range consumer inverters.

Bridge rectifier:

- Four diodes on the back form the rectification network

Isolation between primary and secondary is achieved with an opto-coupler.

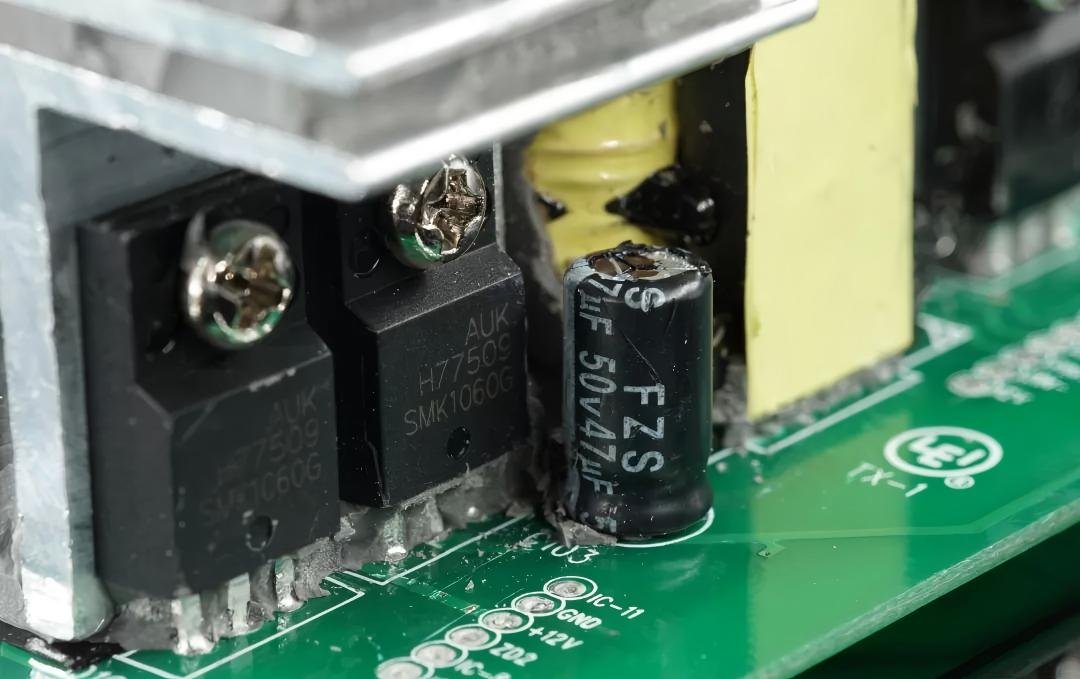

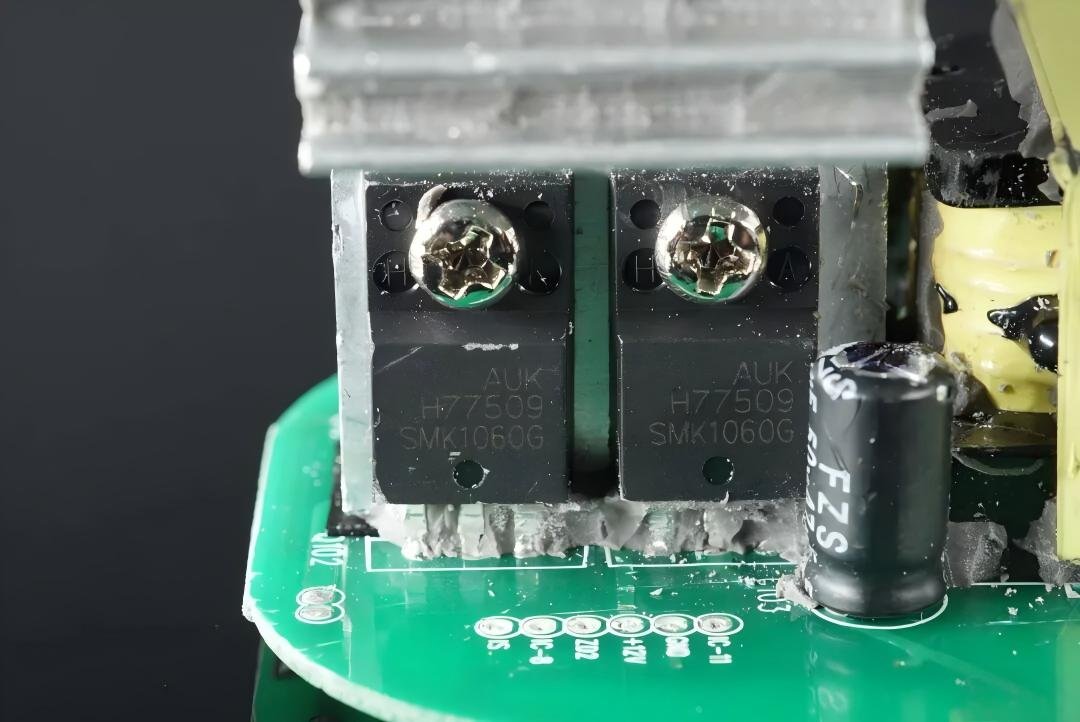

4.5 MOSFET & Component Selection

- Primary boost MOSFETs: SIF110N060 from SINFONET Semi

- Output-stage MOSFETs: KODENSHI SMK1060G

- Capacitors from Danyang Farah brand

Component layout is clean, spaced for heat flow, and optimized for durability.

5. 🔚 Fully Disassembled Overview

The final teardown reveals a well-organized internal architecture with:

- Full potting material

- Dual heat sinks

- Boost stage + transformer

- Output modulation stage

- USB charging module

- EMI filtering

- Quality capacitors and MOSFETs

6. 📝 Final Thoughts

The teardown confirms that the Mijia Car Inverter, despite its compact and consumer-friendly appearance, is built on mature and reliable circuitry. The modified-sine-wave design uses well-known components like KA7500, LM358, standard MOSFET arrays, and robust EMI filtering.

The most impressive engineering choice is the full thermal potting, which significantly improves:

- Heat dissipation

- Vibration resistance

- Long-term reliability

The inclusion of USB charging further enhances real-world usability.

This teardown leads to one clear conclusion:

It’s not high-tech, but it is well-designed, well-built, and thoughtfully engineered — a solid example of how Chinese consumer hardware continues to improve in quality.

7. 🚀 Turning Teardown Insights Into Better Hardware Products

Building a reliable power device — or any consumer hardware — requires a deep understanding of:

- Thermal design

- Electrical architecture

- Component selection

- Structural engineering

- Manufacturing readiness

If you’re developing a new hardware product — inverter, power bank, embedded device, or consumer electronics — we WokooDesign provide:

- Product design & feasibility consulting

- Electronics design (power circuits, MCU, PCB layout)

- Industrial and mechanical design

- Prototype building & verification testing

- Mass-production support and supply chain guidance

By applying the same engineering principles seen inside Xiaomi’s inverter, we help create hardware that is stable, elegant, and ready for real-world challenges.

fast-charging protocol

fast-charging protocol