Rapid Mould Making

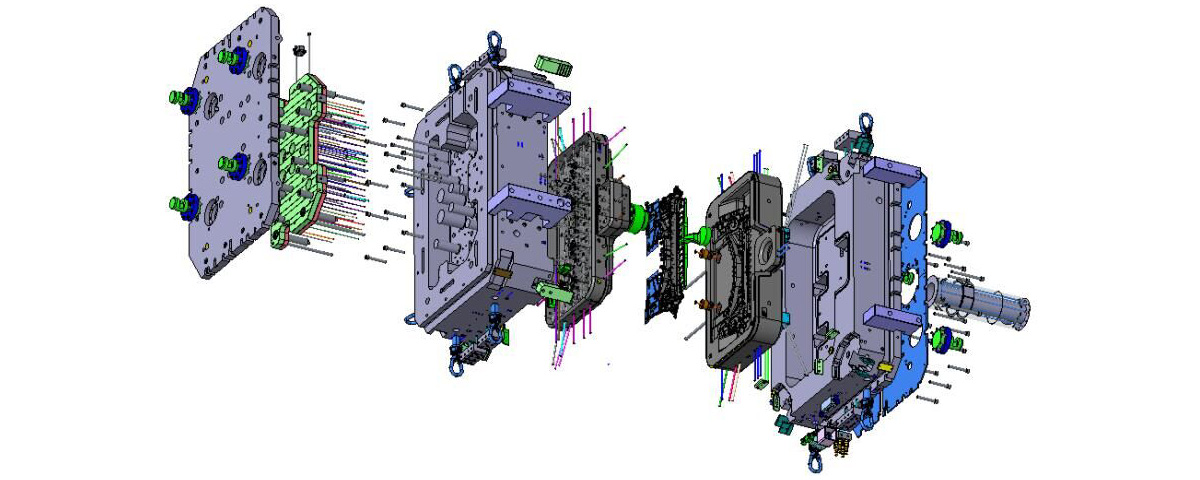

Rapid mould manufacturing means that molds will be manufactured in the fastest way and will affect the life of some molds. There are many advantages: fast delivery time, low cost, reliable quality, flexible engineering changes, etc. It can be textured or highly polished according to the expected surface treatment, without any color restrictions, etc.

It is very suitable for new product development or some products that do not require huge volume (+200k cycle); even some products with complex undercuts can be realized by some special methods, such as hand-mounted blades and auxiliary fixtures. At Hord, we are very good at manufacturing overmolded products, such as metal-plastic, solid plastic-elastomer, plastic, etc.

Almost fast molds can be controlled within 3 weeks, and some molds with simple opening and closing can be completed in 3-7 days. For Western competitors of the same level, maybe they can make simple and fast molds within 3-5 days, but for those molds with undercut sliders or elevators, it will take longer. But in Hodder, the undercut will not affect us much. Hord has hundreds of shared formwork Master United Die (MUD) systems. There are many fast and precise machines for mold making and a very strong technical team that provides support 24 hours a day, 6 days a week. Our team has about 10 years to provide fast molds and small batch production to customers around the world.

Get flexible and fast tools from a trusted manufacturer

For diversified plastic parts and complex products, rapid production tools are widely used because of their strongest characteristics. As the result increased, it experienced a good production time. Of course, it should add many influences and shortcomings of the tool manufacturing process. It provides fast results and focuses on logistics. Based on our manufacturing, Hord RT provides an excellent method to implement every reliable application. It mainly focuses on verified results to keep logistics in transit time. It quickly becomes a shortcoming and includes the tool manufacturing process as timely as possible. Therefore, it contains conventional methods that use appropriate solutions and methods to guide streamline options.

Developed for many industries

When running on high-end applications, Rapid Tooling Making provides the best way to evaluate standard results. Our manufacturer combines production technology with simplified procedures. It enables the tool manufacturing process to start from the most time-consuming step. Therefore, it should be announced with a higher result and has proven to be the solution to all problems. Therefore, it converts the level in a high-end way.

In addition, the tool quickly used multiple methods to develop and produce the process. It leads to participation in the most time-consuming step. This technology can use additive processes suitable for traditional CNC machining.

For plastic parts

It includes companies looking for the best solution, so we provide it professionally without any hassle. We have unique methods to participate in different fields. It is an implementation bridging tool used to access verified results. Therefore, Rapid Tooling Making includes search solutions obtained during the process with customers. Some departments are using plastic components and are called the best production time. This technology is used to capture the effect of additives in direct metal lasers. Our main goal is to make the production process simpler without any hassle.