We performed a teardown of a newly released CUKTECH 10000 mAh 30W fast‑charging power bank. It supports PD, PPS, UFCS, and features dual ports, an LED light strip, and two 21700 cells—balancing compact dimensions with high capacity. Below is our detailed breakdown and how WokooDesign would elevate its design.

Overview Power Bank Teardown

1. Housing & Aesthetics: From Power Bank Teardown to OEM Design

- The case uses matte-finish splitter shell with accent trims.

- Side light strip shows charge level after evaluating the power bank teardown.

- WokooDesign’s optimization:

- Integrate snap-fit ribs or magnetic module insertion to simplify assembly.

- Introduce airflow vents behind the LED strip to enhance passive cooling while retaining aesthetics.

2. Battery & Fixation: Enhancing Structure

- Houses two EVE INR21700/50E cells in black plastic frame, glued in place.

- Thermal pad and thermistor monitor temperature, providing insight during a power bank disassembly .

- Design recommendation:

- Switch to modular battery frames for tool-less unit replacement.

- Add metal heat spreader plate between cells and shell to improve heat dissipation during heavy discharge.

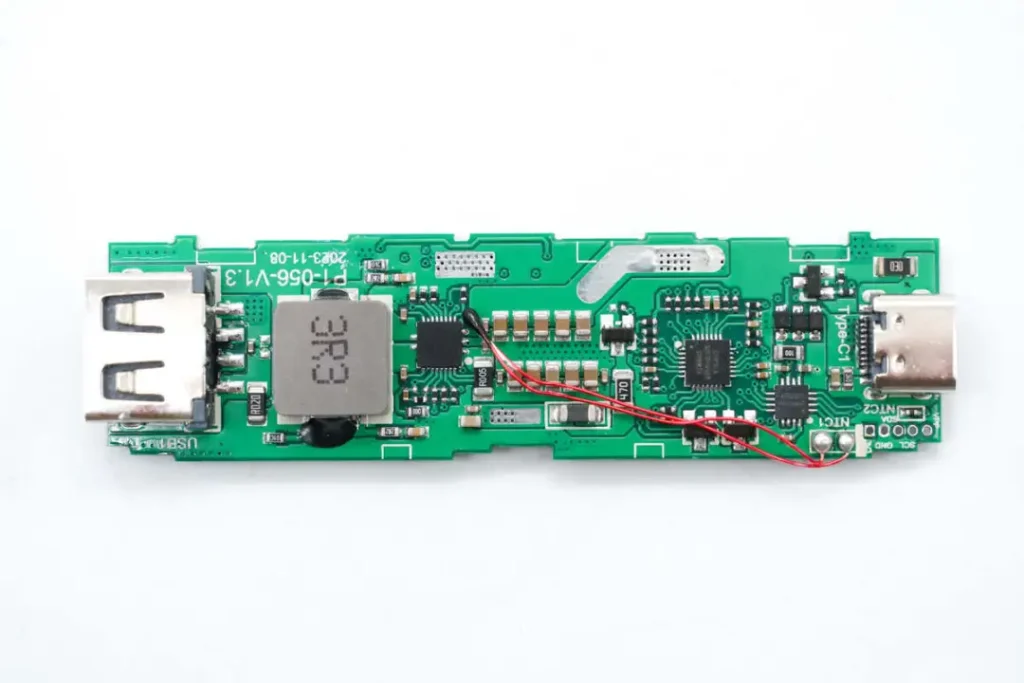

3. PCBA & Component Layout: Power Electronics Flow

- PCBA includes SC8905 buck-boost converter, Chipsea CSU3AF10 protocol IC, CM1020-H protection & CPW6003 overvoltage chips.

- Nickel strips and pogo-solder joints link cells to the board after power bank teardown analysis.

- Optimizations:

- Re-route power traces to separate thermal and RF noise zones.

- Add EMI shielding for the protocol IC to ensure EMI compliance.

- Use copper-infused PCB for thermal management around power MOSFETs.

4. Thermal Management: Solving ‘Hot Mode’

- Thermal pad on converter indicates thermal awareness after observing the power bank teardown.

- But heat spread appears limited to local pad area.

- WokooDesign solution:

- Incorporate internal heat fins attached to the housing.

- Use lid-integrated thermal vias for uniform heat distribution and stability under fast charge cycles.

5. Connector & Mechanical DFM Integration

- USB-A/C ports are through-hole soldered with black insulators. Mold lugs secure ports, indicating points of interest and power bank internal components.

- CUKTECH uses clips and glue to assemble plastic shell halves.

- Optimization:

- Provide drop-test reinforced clips for port durability.

- Use screw-mounted standoffs for structural reinforcement and easier disassembly.

6. Manufacturability & Production-Friendly Design

- The teardown reveals regulatory-grade fast charging, impressive for small size.

- But this increases assembly complexity, especially due to observations during the power bank teardown.

- Design for Manufacturing enhancements:

- Modular internal frame supporting PCB and cells enables parallel manufacturing.

- Standard snap locks reduce glue use and clip tooling costs.

WokooDesign Services Highlight based on Power Bank Teardown

| Design Phase | WokooDesign Solution |

|---|---|

| Industrial Design | Shell redesign with airflow and ergonomic grip |

| Mechanical Engineering | Battery frame with thermal paths |

| PCB Layout Optimization | Thermal management, EMI filtering |

| DFM Support | Clip-snap assembly, production simulations |

| Prototype & Mold | Production-ready 3D models and cost-estimates |

| Manufacturing Liaison | Vendor communication and PPAP support |

✅ Final Takeaway & Next Steps

- The teardown shows compact 30W performance packed in sleek housing, balanced design.

- But several enhancements in thermal, structural, EMI, and manufacturing design could elevate product quality and reliability, as a power bank teardown has revealed.

- This is where WokooDesign steps in:

- We refine your prototype for fast manufacturing.

- We optimize your design for performance, durability, and scale.

🔧 If you’d like us to let your custom power bank design improvement be better—send us your product for teardown or existing samples. We will provide a tailored design and prototyping service to help you launch faster and smarter.